Different methods for cutting materials

In the case of oxyfuel, plasma and laser cutting, thermal energy is used to heat materials up to ignition, melting or evaporation temperatures. Flame cutting and laser cutting with oxygen use the exothermic energy of the oxygen reaction in the process. Flame and laser beam heat material only until ignition temperature is reached. In plasma cutting and laser cutting with nitrogen, the material is heated up to melting temperatures and the cutting gas blows out the melt. The choice of cutting gas needs to be adapted to application for best performance.

Cutting methods

Flame cutting is a combustion process. It is not the heating flame itself that does the actual cutting but an oxygen jet, which burns the material during the heat formation and transports the combustion products (slag) away from the cut. Before cutting can begin, the steel has to be heated to ignition temperature by means of a gas flame. The choice of fuel gas affects cut quality and the time used for preheating.

Flame cutting can be used for cutting mild and low-alloyed steel in thicknesses up to more than 1000 mm. The cut quality also depends on the surface of the work piece and can be affected by different types of shop-primer. The use of several burners for straight cutting, phase cutting and joint preparation is an example of the versatility of the cutting process. The process is also easy to mechanize.

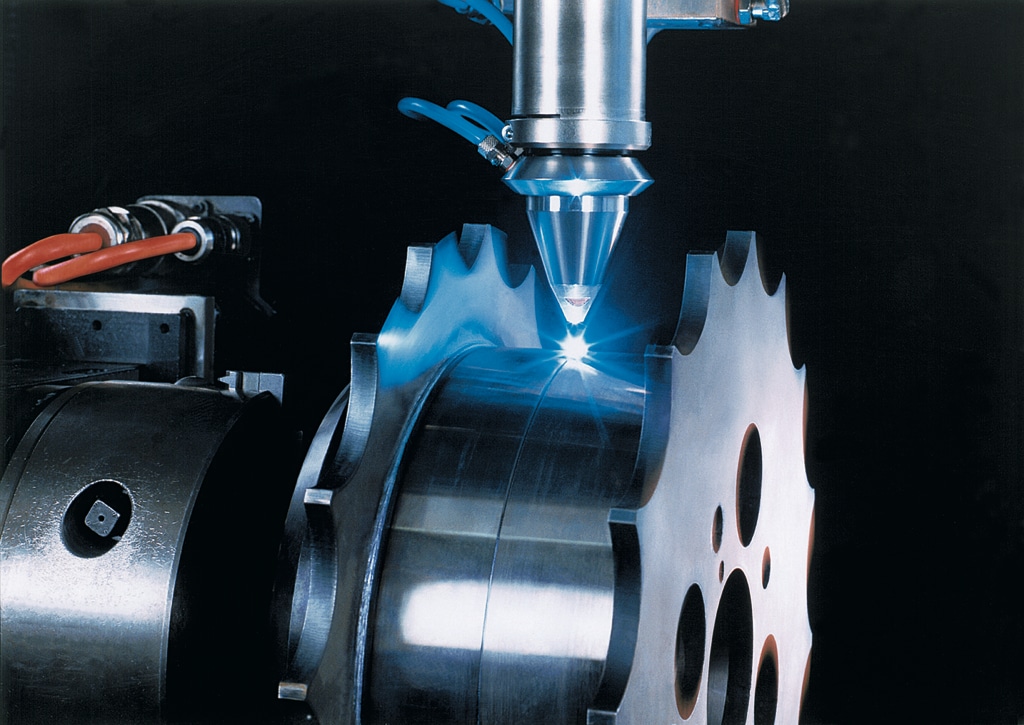

Laser is best suited for high precision cutting of thin pieces. The cut quality is so high that the pieces can be used directly or sent to further processing without the need for post-cut finishing. The focused laser beam is so powerful that it directly melts and vaporizes the material to be cut. Laser can also cut many other materials besides metals, such as plastics, wood etc.

The application determines which of the gases, oxygen or nitrogen, is better suited for the task. Oxygen reacts exothermically (generates heat) with the material, which enables faster cutting speed than with nitrogen. As a result, oxygen is the most important cutting gas for cutting mild and low-alloy steels. Meanwhile it is not well suited for cutting stainless steel due to the cut surface losing its corrosion resistance. Aluminium surfaces cut with oxygen are uneven and burred. To get a clean, oxide-free cut surface, nitrogen must be used when cutting these materials. Our dedicated LASERLINE® gases and gas supply systems help to ensure that your cutting activities continue to be high-tech and economical from start to finish.

Plasma cutting is a melt-cutting method, where the energy of the hot plasma arc is used for blowing away molten material. Plasma is a state of matter where the gas that is ionized, which means that it consists of positive ions and electrons causing the media to be electrically conductive. Plasma melts the material locally and the melted material is removed from the cut by means of the gas jet. For example, mild steel is often cut with oxygen or nitrogen as plasma gas while stainless steel is often cut with an argon (or nitrogen) based gas including hydrogen as a reducing media.

- Flame cutting

- Laser cutting

- Plasma cutting

Flame cutting

Flame cutting is a combustion process. It is not the heating flame itself that does the actual cutting but an

oxygen jet, which burns the material during the heat formation and transports the combustion products (slag)

away from the cut. Before cutting can begin, the steel has to be heated to ignition temperature by means of a

gas flame. The choice of fuel gas affects cut quality and the time used for preheating.

Flame cutting can be used for cutting mild and low-alloyed steel in thicknesses up to more than 1000 mm. The cut

quality also depends on the surface of the work piece and can be affected by different types of shop-primer. The

use of several burners for straight cutting, phase cutting and joint preparation is an example of the

versatility of the cutting process. The process is also easy to mechanize.

High purity laser gases for protecting the beam

A safe, reliable and efficient gas supply is one of the most important elements to consider when investing in a new laser machine or optimizing your existing laser operations. Linde will effectively support you through that process. Resonator gases are used in gas lasers to generate laser light. The gas mixture for a CO2 laser contains helium, nitrogen and carbon dioxide.

Other additives are used for certain laser types e.g. oxygen, hydrogen, xenon and carbon monoxide. Gas mixtures for excimer lasers often consist of halogens, noble gases (krypton, xenon or argon) and buffer gases (helium or neon). A modern carbon dioxide laser requires laser gases of high purity. Excessive amounts of impurities may affect the output of the laser. The lifetime of the optical components may also be affected. In this context, water vapour and hydrocarbons are the most critical impurities.

What do our customers say?

“I am very pleased with Linde as supplier of laser gases and services to our company. I especially appreciate

the

technical support. Quick response times and dedicated, competent Linde technicians are of great value for

us.”

Richard Jorvén, MD and Owner.

Täby Plåtteknik AB

Osta tuotteita täältä

Downloads

Downloads

| Safety datasheets | Product datasheets & brochures |

|---|---|