The CRYOLINE Family

Cryogenic freezing and cooling of foodstuffs using liquid nitrogen and carbon dioxide is a well established technology that has been enhancing food processing for many years.

CRYOLINE MT

Tunnel Freezer.

The CRYOLINE® MT is an in-line continuous tunnel freezer, which uses either liquid nitrogen (LIN) or carbon dioxide (LIC),

depending on your food product and production needs.

It is modular in design, enabling you to expand production by adding additional tunnels for a longer freezing production line.

It is available in several models and belt widths with production rates of 200–2,500 kg/h (440–5,500 lb/h)*.

CRYOLINE CW

Multi-purpose freezer.

Easily switching between IQF (individually quick frozen) mode and standard flat

belt tunnel freezer, the CRYOLINE® CW is a versatile multi-purpose cryogenic freezer.

It utilises the CRYOWAVE controllable vibration technology that provides adjustable agitation for optimum IQF foods,

while also providing the ability to perform as a standard tunnel for many other food types of differing shapes and sizes.

The freezer is available in various models and belt widths with typical achievable production rates of 500–2,700 kg/h (1,100–6,000 lb/h)*.

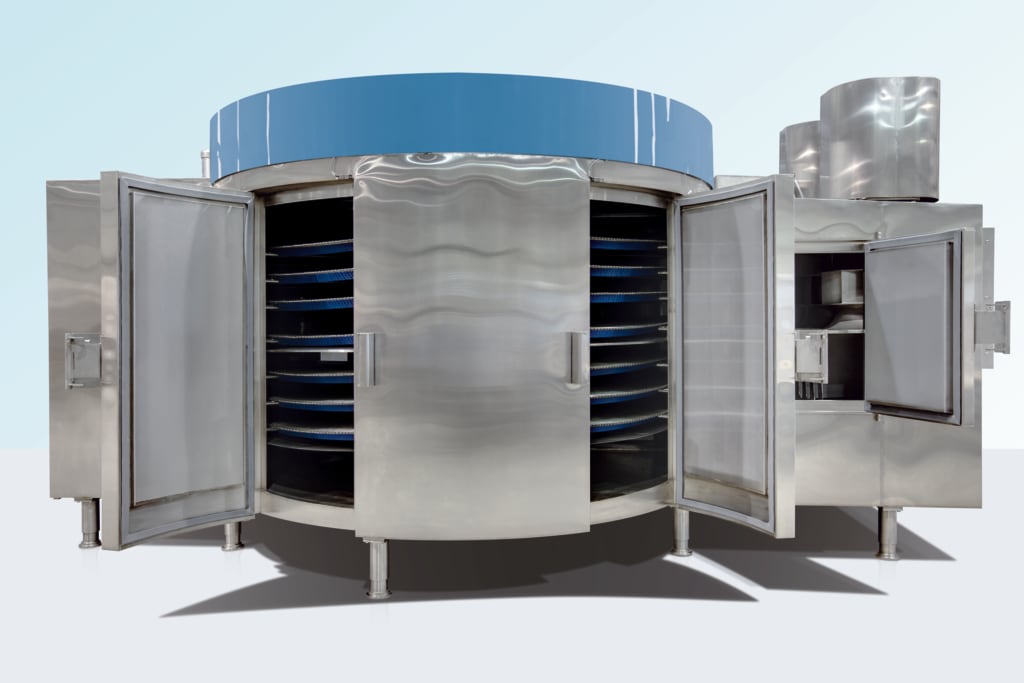

CRYOLINE CS

Compact spiral freezer.

The CRYOLINE® CS is a cryogenic self-stacking spiral freezer.

Providing a high production capacity within a small space, it is suitable for a wide range of food products.

The CRYOLINE CS is targeted at medium volume customers with typical achievable production rates of 1,200–2,400 kg/h (2,600–5,300 lb/h)*.

CRYOLINE PE

Pellet/moulded-shape freezer.

This is the only cryogenic freezer designed to produce formed food shapes.

Processors interested in portion control of frozen ingredients for sauces, purees, soups and other liquid food products can achieve weight proportioning and unique logo imprints.

The CRYOLINE® PE is perfectly suited for processors servicing the food service and ready meals industries as well as consumer markets.

CRYOLINE XF

High performance spiral freezer.

The CRYOLINE® XF is built for large capacities from 2,500 to 7,500 kg/h (5,500-16,500 lb/h)*.

Its patented technology delivers twice the heat transfer rate of commercial spiral freezers, making it twice as powerful.

The CRYOLINE XF provides a smaller footprint, a higher production capacity and is more efficient than standard cryogenic spiral freezers.

It is suitable for high temperature and high moisture products, e. g. cooked poultry, seafood and prepared meals.