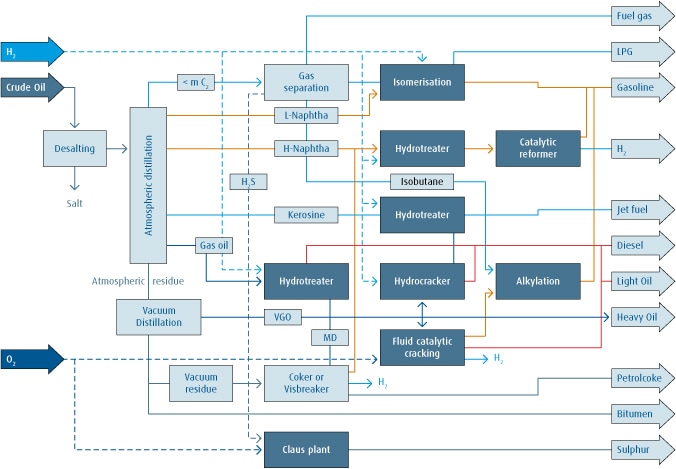

Industrielle gasser spiller en afgørende rolle i petrokemisk forarbejdning og raffinering

I den petrokemiske industri bidrager industrielle gasser til en række vigtige opgaver, ofte som usynlige hjælpere og problemløsere. De bruges ikke kun som petrokemiske råstoffer, men også som reaktanter og oxidative stoffer. Derudover assisterer de ved hydrotreatment, procesintensivering, proces- og kvalitetskontrol, inertisering samt opbevaring og transport.

Gassernes rolle fra udvikling til implementering

Linde tilbyder en bred vifte af gasrelaterede løsninger, der spænder over state-of-the-art applikationsteknologier, end-to-end forsyningsløsninger, og udviklingsværktøjer som for eksempel eksperimentelle opsætninger, beregningsprogrammer til procesdesign og software til understøttelse af sikkerhedskompetence. Lindes eksperter arbejder tæt sammen med dig for at udvikle og optimere den industrielle gasapplikationsløsning, der passer bedst til dine behov. Derudover understøtter vi alle faser af projektets livscyklus, fra projektering og design til implementering og opstar

Would like to learn more about Petrochemical processing and refining

Not only legislation but more extensive processing of residues and higher diesel demand compared with petrol will also increase hydrogen's demand.

There are various hydrotreating processes in a refinery. To name a few:

● Hydrodesulphurisation: sulphur compounds are hydrogenated to hydrogen sulphide H2S as feed for Claus

plants

● Hydroisomerisation: normal paraffins are converted into iso-paraffins to improve the product

properties (e.g. RON)

● Dearomatisation: aromatics are hydrogenated to cyclo paraffins or alkanes

● Hydrocracking: long-chain hydrocarbons are cracked to shorter chains in the gasoline range.

Main processes for hydrogen production:

● Steam reforming of methane or other hydrocarbons

● Gasification of organic feedstock to syngas (H2/CO)

● Recovery from gaseous waste streams

● Electrolysis of NaC

Process consulting, financing, erection and start-up are all services offered by Linde. We can also provide

hydrogen plant operation (over-the-fence-supply), maintenance and repair and emergency supply arrangement to

ensure that your business is working at its optimum.

Hover on the image to enlarge it

Claus-anlæg i raffinaderier behandler koncentreret svovlbrinte (H2S) og omdanner det til rent svovl.

De kan også fjerne forurenende stoffer, navnlig ved at opløse ammoniak. Strengere miljøbestemmelser fører til produkter med lavere svovlindhold.

Som følge deraf er belastningen på Claus-anlæg med svovlbrinte og ammoniak stigende og Claus-anlæg kan blive en flaskehals.

Problemet kan løses ved oxygenberigning af forbrændingsluften. Dette øger kapaciteten betydeligt.

En ny type brænder sikrer en fremragende blanding af svovlbrinte og oxygenberiget luft over et stort belastningsområde..

Fordele ved oxygenberigning:

● Øget kapacitet af Claus-anlæg

● Øget produktivitet uden at ændre trykfaldet

● Mere effektiv behandling af ammoniak, der indeholder råmaterialer

● Mindre besvær for efterfølgende gasrensning (reduceret nitrogenstrøm).

Katalytisk krakningsproces af væsker (FCC - Fluid Catalytic Cracking) konverterer primært vakuum-gasolie fra destillation af råolie

til benzinprodukter og brændselsolier. FCC bryder tungere og mere komplekse kulbrinter ned til lettere kulbrinter.

Råmaterialerne er primært vakuum-gasolie, ofte blandet med raffineringsrester. De vigtigste produkter er

gasfraktionering (hovedsageligt C3/C4), fraktionering af væsker samt koks (fast dannelse på katalysatoren).

FCC oxygenberigelse indebærer tilsætning af et kontrolleret flow af gasformig oxygen til forbrændingsluften.

Oxygenberigelse i gendannelsesprocessen gør at operatøren i raffinaderiet kan:

● øge FCC-kapaciteten

● Have større fleksibilitet i valget af råmaterialer

● bruge tungere råmaterialer

● forøge konverteringen og udbyttet af råolie

● reducere biprodukter.

In order to help control particulates, sulfur dioxide and NOx emissions from the FCC we offer the LOTOX®

technology. LOTOX® is a patented innovation that uses ozone to selectively oxidize insoluble NOx to highly

soluble species that can be easily removed in a wet scrubber. The benefits include increased capacity,

greater flexibility in the choice of feeds, increased conversion rates and reduced emissions.

Delvis iltningsanlæg bruges til at danne brint, kulmonoxid,

kuldioxid og vand fra restprodukter (væsker, meget viskøse kulbrinter) fra raffineringsprocessen

Produkterne kan benyttes som syntese gas, gas eller råmateriale for generhvervelse af brint.

Med skræddersyet iltforsyning til delvis iltning kan vi tilbyde følgende fordele:

● Renere og bedre genbrug af restkoncentrationer

● Bredere økonomisk base for raffinaderiet

● Højere fleksibilitet gennem en bredere vifte af produkter

● Håndtering af raffinaderiets råmaterialer over et bredt udvalg

We offer a vast service portfolio dedicated specifically to the needs of refinery operations. Pressure,

temperature, purity and volume requirements can vary significantly across a range of highly specialised

applications.

Many refinery operators rely on our nitrogen services – sometimes in combination with other gases – to

support the following applications:

● Drying and purging: Humidity in pipelines can delay start-up or compromise productivity for days. Purging

with large streams of gaseous nitrogen enables pipelines to be dried and heated in a controlled manner, thus

accelerating start-up and boosting productivity. We can supply nitrogen at flow rates of up to 25,000 m3/h

and at a pressure of up to 700 bar for these applications.

● Inerting and blanketing: We supply inert gases such as nitrogen or carbon dioxide (CO2) to bring oxygen

concentrations down to a safe level in environments with the potential for fire and explosions.

● Pipeline pigging: A pig is sometimes pressed through a duct or pipeline that requires cleaning or

inspection, especially if it contains viscous material. We supply gaseous nitrogen for this purpose. It is a

highly effective, safe and dry pressure medium, supporting a wide range of pressures, temperatures and

volume flow rates.

● Leak and pressure testing: We supply a special nitrogen/helium mixture to detect even tiny leaks and leakage

rates at operating conditions with pressures of up to 250 bar. The helium acts as an easily detectable

tracer gas as it is inert and diffusible. This is an effective, economical solution that enables operators

to rapidly remedy defects. We also supply high-pressure nitrogen for testing at pressures of up to 700 bar.

● Reactor cool-down with hot stripping: With our hot stripping and CATCOOL™ processes, refineries can shorten

by days the window needed to cool down high-temperature facilities in preparation for inspection. This inert

process technology relies on controlled streams of large volumes of cold nitrogen to reduce production

downtime.

● Pipe and ground freezing: Cryogenic nitrogen can be used to temporarily seal and freeze pipe sections for

installation or repair work. This smart solution eliminates the need to drain and shut down the entire

piping system. This method can also be used to freeze the ground for construction work.

Køb produkterne her

Downloads

Downloads

| Sikkerhedsdatablade | Produktdatablade og brochurer |

|---|---|