The raw tonnage of paper produced and consumed globally every year continues to rise. Dwindling demand for print and writing paper is being more than offset by rising demand for lightweight packaging materials, tissue paper and eco-friendly boxes. So much so, in fact, that new mills are being built and many existing mills are looking for ways to increase their capacity. It is estimated that the market will continue to grow dynamically over the coming decade.

However, the industry also faces consolidation, globalisation and competitive challenges. Rising energy prices and growing environmental concerns are placing additional pressures on this extremely energy- and resource-intensive business.

Innovative technologies to unlock efficiency gains

However, there is a growing number of opportunities to optimise resource and cost efficiency. The adoption of best-in-class, emerging technologies coupled with innovative energy efficiency measures can fine-tune small but essential links in the overall process flow.

In addition, the growing use of biomass as a self-sufficient source of energy – with its low carbon intensity – is helping to decarbonise operations and support the transition towards a low-carbon bioeconomy. New business concepts are maximising the potential of wood as a raw material by cascading it along an extended value chain. Hence wood and wood fibre are being turned into bio-based fuels or novel products and materials for the food, textile, cosmetics and pharmaceutical industries. This is further contributing to resource efficiency and reducing environmental pressure.

For more information - contact us

Doing more with less

As a reliable, trusted partner, we have been working closely with the pulp and paper industry for many decades. Our aim is to help our customers maximise resource and cost efficiency by fine-tuning their process flows. Our experience, backed by our extensive and continued research in this area, has shown that gas-enabled application technologies often offer an uncomplicated, low-investment route to rapid and quantifiable efficiency gains.

Spirit of partnership

We work closely with our customers and listen to them to gain a full and deep understanding of their wider process flow. This enables us to tailor our innovative ACTICO® and ADALKA® gas solutions for pulp and paper to the customer’s specific quality and processes. The customer benefits from reduced water consumption, increased washing capacity or optimised pH control, for instance. At the same time, we support customers in achieving their sustainability goals by reducing consumption of bleaching agents, replacing harmful chemicals with gases, monitoring emissions with our HiQ® specialty gases and controlling emissions with our LOTOX™ high-performance NOx removal technology.

The big picture

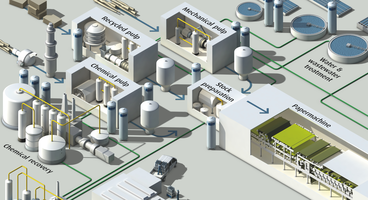

Looking beyond our dedicated ACTICO and ADALKA pulp and paper solutions – several of which are patent-protected – and our tailored injecting and dissolving equipment, customers also rely on us for a range of complementary process technologies along the wider pulp and paper value chain. Our SOLVOX® and SOLVOCARB® gases and application technologies, for example, contribute to the efficiency and environmental performance of wastewater treatment operations. In addition, we support the move towards an integrated bioeconomy by helping to capture carbon emissions, turn residue into valuable products, and generate biofuels through steam reforming. Last but not least, the challenges associated with fires in biomass storage silos can be effectively managed with our innovative biomass fire suppression solutions.

This wide portfolio of application technologies is rounded out by expert consulting, professional training, ACCURA® and SECCURA® gas management services, security of supply across all industrial and specialty gases and a wide choice of supply modes –ready-to-run on-site ozone generation solutions included.