Although the pulp and paper industry is growing as a whole – driven largely by rising demand for packaging, tissue paper and pulp for hygiene products – there are various challenges on the horizon. According to experts at McKinsey & Company, this sector is going through the most substantial transformation it has seen in many decades, prompted by structural changes, consolidation, and ever-rising specialisation. Given dwindling newspaper sales, for instance, many paper mills are looking to position themselves for growth by converting from graphic to packaging paper. In the search for value-creating growth opportunities, many pulp mills are also looking to branch out into biorefinery products.

In addition to the usual cost constraints, executives are thus under pressure to invest in their innovative capabilities, improve efficiency, and explore new growth paths. One way of doing this is by teaming up with a strategic partner such as Linde. Building on its deep and long-standing process know-how, Linde is uniquely positioned to help pulp and paper customers solve production-related problems, increase productivity in an eco-friendly way and leverage biorefining growth. We have also developed a number of innovative gas-enabled process solutions specifically to address common challenges in pulp and paper operations.

Would you like to speak to someone - contact us

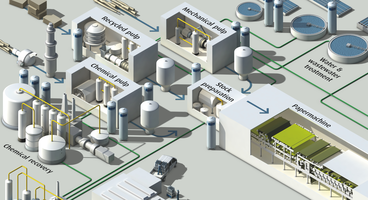

Many key players in the industry rely on us, for instance, to help increase capacity without investing in new and larger equipment, reduce dependence on hazardous chemicals, improve pulp washing efficiency and stabilize pH, alkalinity and calcium levels in papermaking. Experience has shown, for example, that our ACTICO® CO2 pulp wash solution can facilitate the transition from bleached to unbleached pulp, helping mills to convert from paper to cardboard.

We also support pulp and paper customers with other core processes such as water treatment. Our SOLVOCARB® wastewater treatment solutions are a cost-effective, environmentally sound way of controlling pH with accuracy and avoiding non-compliance issues. SOLVOX® oxygen enrichment solutions, on the other hand, use oxygen to support natural biological processes in wastewater and keep pollution levels in treated effluent at safe levels.

Complementing this broad and deep solution portfolio, we help our customers to maximise their investment in gas-enabled technologies through value-added services such as expert consulting, professional training and ACCURA® and SECCURA® gas management services. Last but not least, customers count on us for security of supply across all industrial and specialty gases and best-fit supply schemes thanks to a wide choice of supply modes – ready-to-run on-site ozone generation solutions included.